In-House production

From 3D laser cutting to powder coating, our in-house manufacturing ensures precision and quality at every step. With our state-of-the-art manufacturing processes and expert craftsmanship, we bring to life a wide range of indoor and outdoor training rigs, systems, and elements, that are designed to inspire and challenge athletes of all levels. We'll take you behind the scenes of our production and shed light on the meticulous steps involved in creating our exceptional products.

3D Design

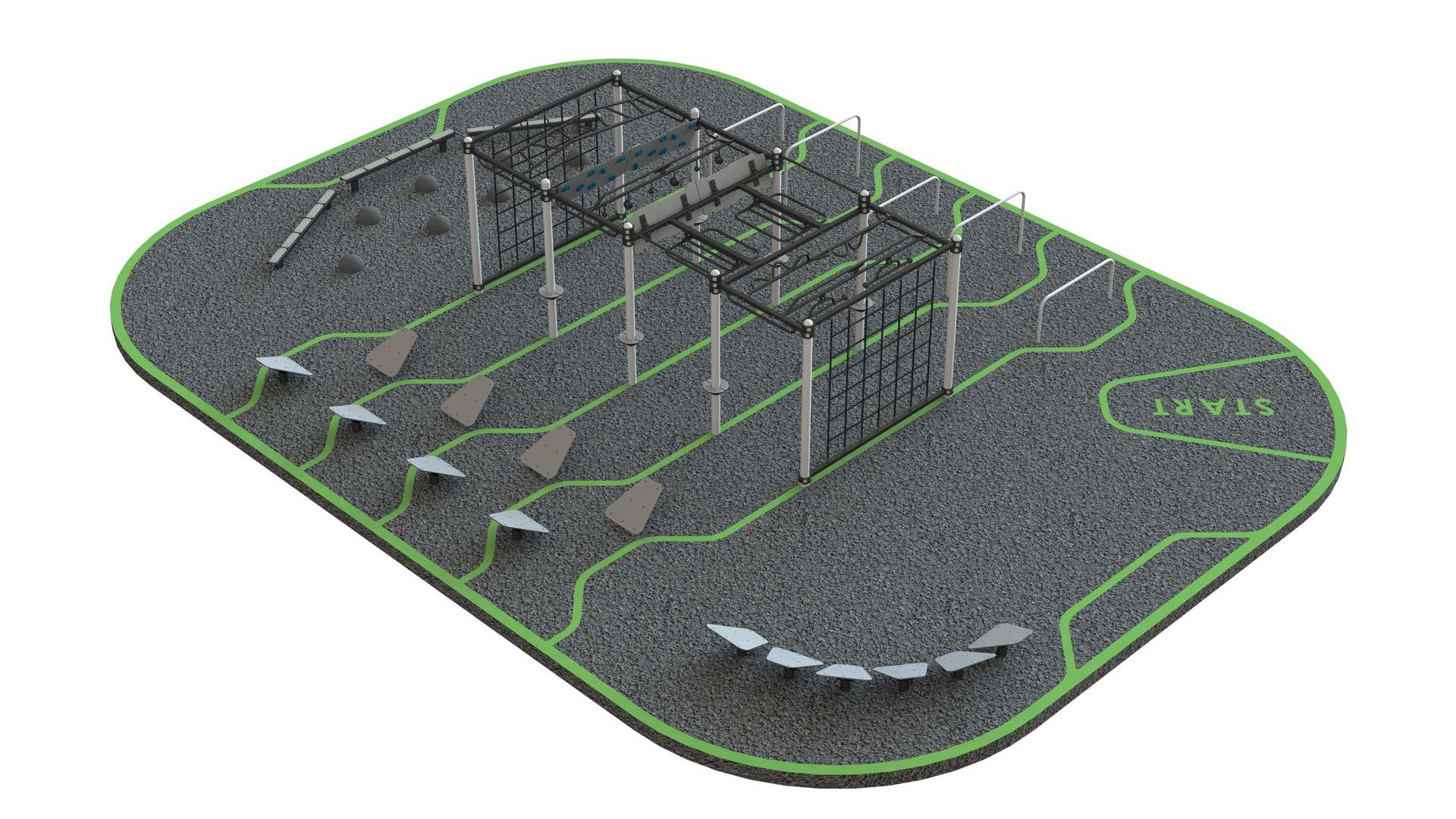

At the heart of the new project production cycle lies the initial phase of 3D design. Our team of experts diligently designs each rig and station, carefully considering various factors such as functionality, aesthetics, and durability.

We employ advanced 3D design software and conduct comprehensive stress tests to ensure optimal performance and safety.

Additionally, we take into account the surrounding environment, including other objects and the topography, to create visuals that seamlessly integrate with the surroundings.

As a result, we can provide raw 3D and 2D files, such as DXF and SKP formats, that can be utilized with other software for general planning projects.

This approach ensures that our clients receive not only exceptional fitness equipment but also valuable resources for their overall planning needs.

Explore our Idre Fjall Fitness and Ninja Park project

Crafting the foundation

Our manufacturing facility serves as the beating heart of our enterprise. Equipped with cutting-edge technology, our skilled team excels in various processes, including 3D laser cutting, welding, bending, shot blasting, and powder coating.

These techniques form the foundation of our production, ensuring the utmost precision and durability in every piece we create. No challenge is too great for our experts, as they eagerly embrace the opportunity to bring your most incredible ideas to life.

We have access to high-end equipment such as TRUMPF lasers, FARO quantum arms, and Hedelius equipment. With decades of experience in metallurgy and mechanical engineering, we have focused on providing the best possible Functional fitness equipment on the market, our specialty being custom fitness solutions.

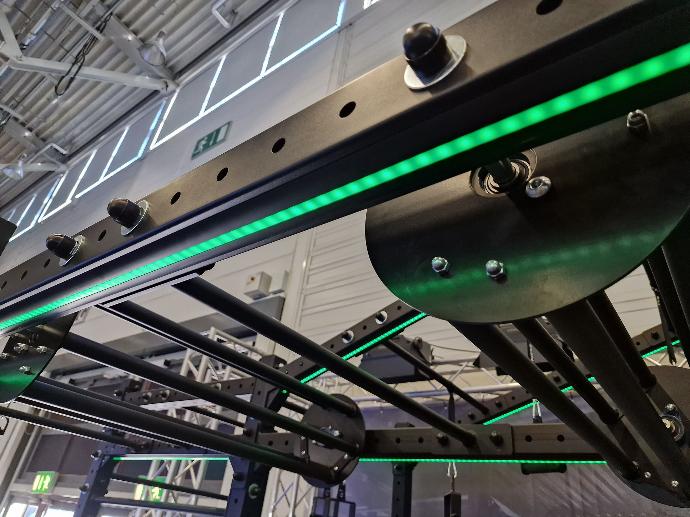

Engineering excellence

The pillars of our indoor training rigs are built to withstand the test of time. With a sturdy construction of 80x80mm and 3mm wall thickness, they provide a robust foundation for your workouts. The height options of 2.40m and 2.80m, with the option to extend by 1.05m, allow for individual customization to suit your space.

The laser-cut holes, with a pitch of 8 cm and a diameter of 17 mm, provide easy installation and adjustment of attachments. Additionally, the poles are designed with drainage holes in the leg to prevent rust when used outdoors.

The height of the pillars of our outdoor training stations is 2,50m with 108mm diameter.

Pillars are coated with polymer zinc primer and powder-coated in various RAL colors.

All other parts are also primed and only coated in RAL 9005 Jet Black Sandy Grip coating. It is a special coating designed for better grip on the surface during physical exercise performance.

Splash of color and weather resistance

The pillars and vertical bars are coated with a polymer primer containing high zinc content, followed by a polymer paint in the RAL palette of your choice. This not only enhances the visual appeal but also protects against the elements.

For those seeking extreme weather resistance, we offer the option of hot zinc coating, which further fortifies the frame and makes it ideal for military or police applications.

Versatile accessories

Our products are fully customizable, reflecting your ideas in color, size, and personalized attachments. Indoor and outdoor training rigs are complemented by horizontal bars, beams, and shelves that add versatility to your workouts. Powder-coated in sleek black RAL9005 Jet Black with sandy grip effect, these elements are specially roughened to enhance grip and ensure stability during training sessions.

Reliable connections

When it comes to the structural integrity of our rigs, we leave no room for compromise. We utilize galvanized Wurth bolts, available in lengths of 110mm and 120mm, ensuring secure and long-lasting connections.

Each bolt is packaged in shrink-wrapped bags of 10 pieces, ready for easy installation. Proper washer placement is meticulously observed during assembly to prevent any deformation and ensure optimal performance.

Warranty for structural integrity of our indoor and outdoor stations 15 years.

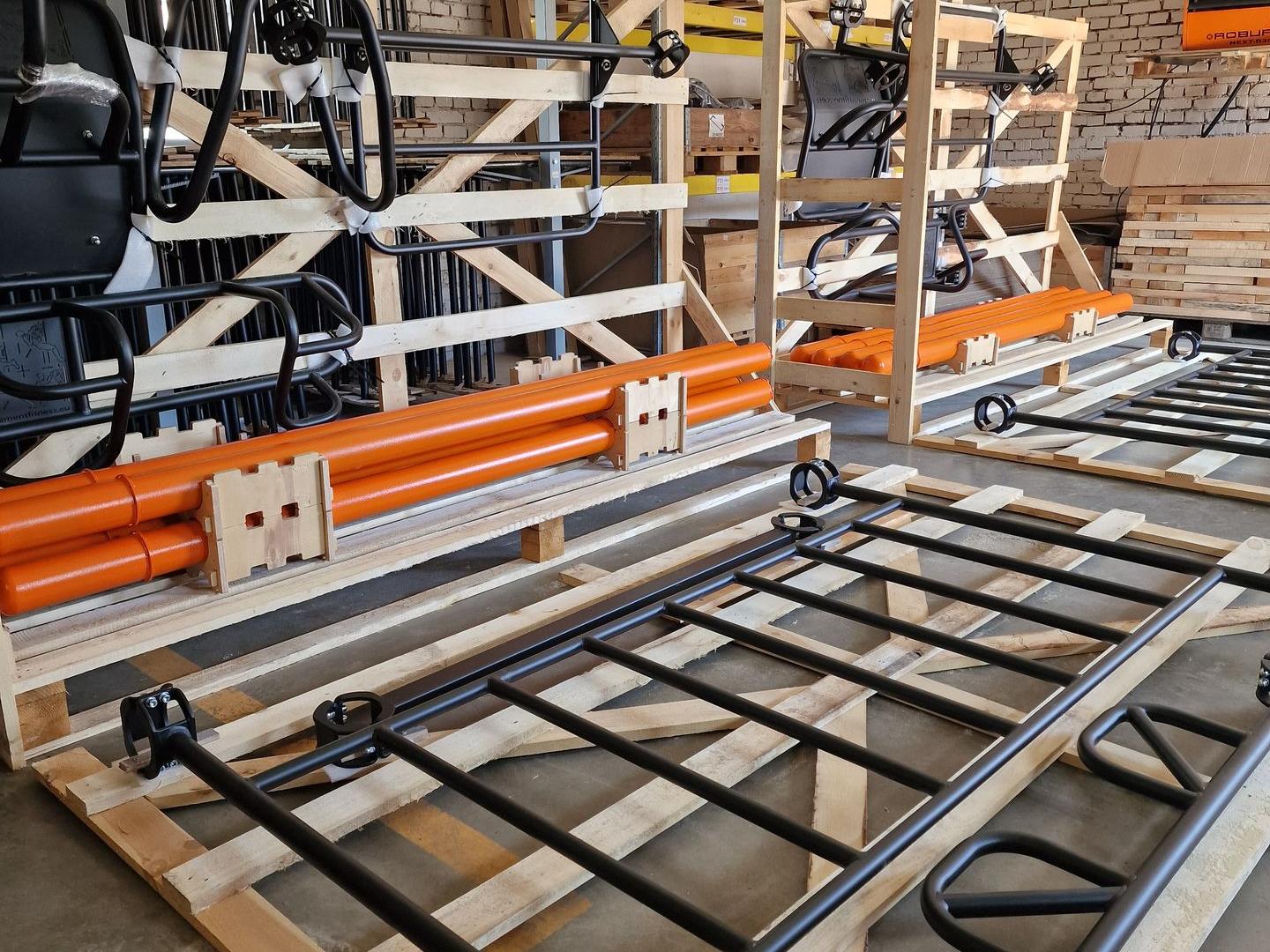

How we bring quality to your doorstep

Our warehouse and dispatch center are where all the magic happens. It's here that we receive and carefully inspect all the components that go into our fitness equipment.

From there, our team of skilled technicians assembles the parts into finished products, paying close attention to every detail to ensure that each piece is built to our exacting standards.

Every piece of equipment is carefully wrapped and packaged to protect it during transit. We use a combination of bubble wrap, foam, sturdy wooden crates, and pallets to ensure that every product arrives at its destination in pristine condition.

We keep most of the components in stock, so we can provide fast delivery even for the most non-standard solutions. The presence of a distribution network that covers more than 15 countries in Europe allows us to ensure uninterrupted supply.

OEM / MANUFACTURING SOLUTIONS

Element Fitness offers functional, ninja, OCR, CrossFit, and military training solutions under your brand!

The Element Fitness Cross Training System comes with either a No-Brand or custom-branded assortment.

We offer:

- Custom RAL color coating or hot dip zinc coating on pillars, even on smaller orders.

- Branding solutions like logo plates, spray logo application, and vinyl sticker solutions.

- Design and 3d visualization of No-Brand rigs or branded parts and equipment.

- Flexible order quantities on rig parts.

- Storage of the custom parts in our warehouse for convenient drop-shipping.

Provide your contact information, and our team will promptly get in touch to furnish you with detailed information regarding our equipment and manufacturing options